Rumored Buzz on Sheroz Earthworks

Rumored Buzz on Sheroz Earthworks

Blog Article

Sheroz Earthworks Fundamentals Explained

Table of ContentsThe Only Guide for Sheroz EarthworksSome Known Details About Sheroz Earthworks Getting The Sheroz Earthworks To WorkExamine This Report about Sheroz Earthworks10 Simple Techniques For Sheroz Earthworks

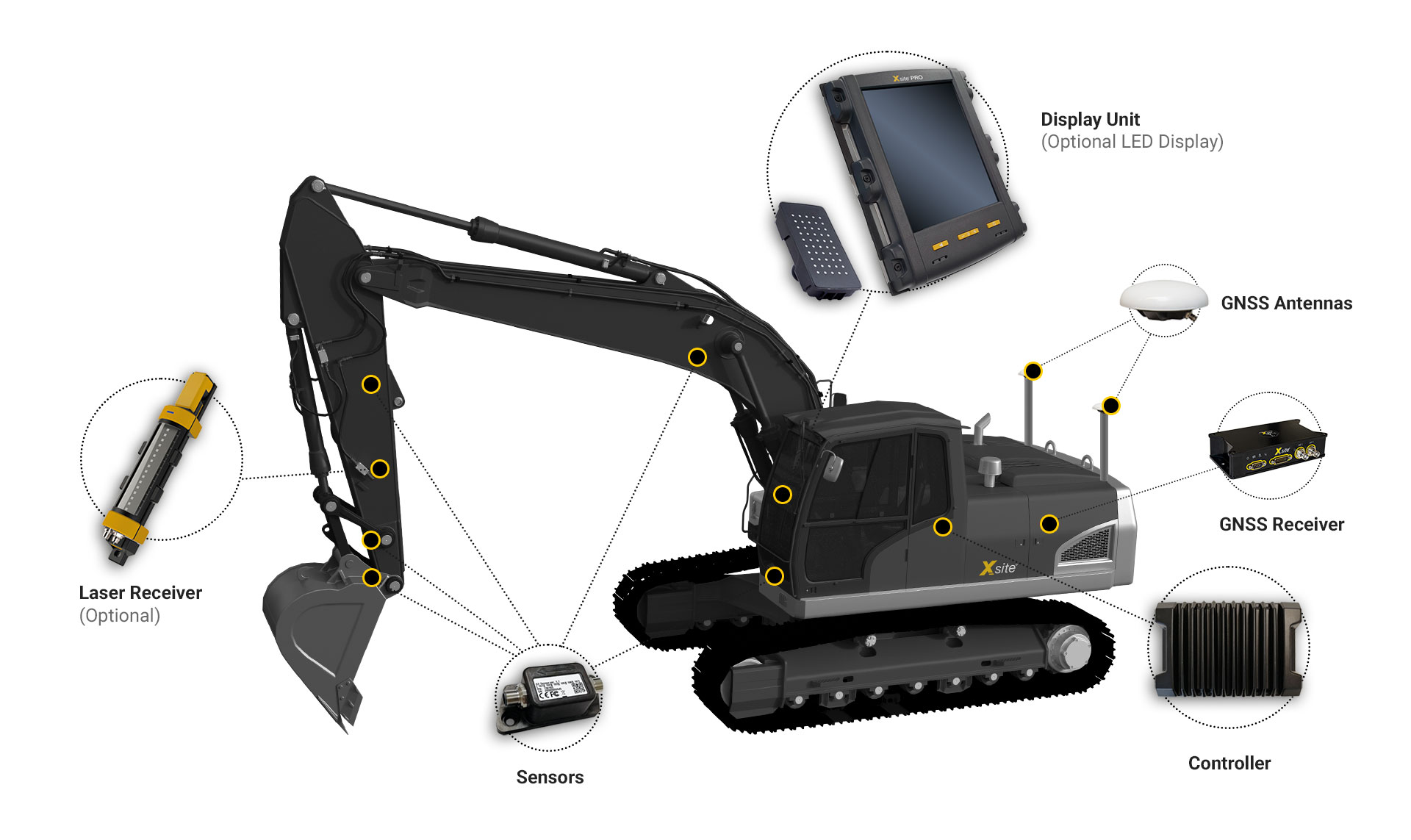

For any type of earthwork specialist, it is important to perform job with high quality, precision, and on timetable. Using device control in work equipments makes it possible for enhancing the various phases in the earthwork process, from intending to the upkeep stage - topcon laser level. The machine control system aids the device driver in attaining the target plane rapidly and easily

The machine control system overviews the operator with centimeter precision. Remote support conserves time and money, as it minimizes downtime in jobsites.

An Unbiased View of Sheroz Earthworks

Our system's components are very carefully made to stand up to the rough problems of building and construction websites. Comparison of the exact same project performed making use of machine control versus the standard technique exposes that, on average, the conventional technique needs 50% more time to achieve the same job as the technology-assisted method.

Get in the Xsite machine control system; it's below to give you with a substantial advantage when working with earthmoving machinery. Discover exactly how Xsite Equipment Control can improve your performance and guarantee work security! Xsite Equipment Control systems can be installed to any excavator from mini excavators to big mining excavators.

Just how does machine control job? In 2D systems, the device is equipped with calibrated inclination sensing units. These sensing units are installed on the pre-determined parts of the device in excavators the sensor are typically placed to the structure, boom (or booms), digger arm and to the quick coupler - trimble repair parts. By using the information gotten from these sensors the system can compute the precise position of the excavators bucket pointer in relevance to a recommendation point.

The system is extremely easy to find out the fundamentals can be taught in under one hour of training. With Xsite you don't have to stress over learning all the ideas and method at as soon as. Additional training and instructions are constantly available over remote support when required. Call your local Xsite dealership to figure out even more! How does the remote support work? A wireless internet link makes it possible to establish a remote connection in between the device control system and the service facility.

More About Sheroz Earthworks

Xsite Machine Control systems sustain open basic documents formats, enabling smooth info flow from one system to another. Depending on your choice of system (with or without placing, i.e., 2D or 3D), your maker is furnished with disposition sensors, a controller unit, and a display/operating panel.

Many software and hardware remedies exist to aid figure out a maker's existing setting on the earth and contrast it with a preferred design surfaceand construction drivers can do even more to take advantage of the benefits. Equipment control is the use of numerous positioning sensors and a display to supply the operator with a referral between the setting of the bucket or blade and the target quality.

Relying on the setup, maker control systems can supply the driver with a straightforward aesthetic overview to pail or blade setting, or can instantly move the blade to grade by speaking to the device's hydraulics - https://sitereport.netcraft.com/?url=https://sheroz.com.au. There are equipment control systems available for nearly any equipment: , dozers, excavators, dirt and asphalt compactors, scrapers, trimmers, crushing equipments, and pavers

Not known Details About Sheroz Earthworks

Maker control Visit Website can additionally help raise productivity and reduce overall expenses. Building and construction equipment without device control will come to be a point of the past and the benefits obtained from it will certainly be countless.

Trimble maker control systems provide a myriad of advantages to any person that utilizes earthwork equipment and, at EarthCalc, we can offer you with 3D declare your maker control-enable devices. Unsure if maker control is worth the expense? Take into consideration the adhering to reasons you require to consider this choice.

Utilizing general practitioner straightened with your 3D layout files, these systems basically ensure that you will get rid of or place the appropriate amount of material at the construction site. On the majority of building websites, rework is a common and discouraging fact, however with Trimble machine control, you can get rid of the need for rework.

Sheroz Earthworks - The Facts

Often, with Trimble maker control, you can get rid of excess equipment at a specific job website. A job that might have called for the use of 3 or four pieces of excavating tools currently may require just two pieces of tools to accomplish the exact same job in much less time. This permits you to move your tools to an additional task site and handle numerous work at one time.

Report this page